HelixMark® Platinum Silicone Tubing

Platinum-cured silicone tubing, stoppers and gaskets

The world’s leading medical device, pharmaceutical and biotech companies rely on HelixMark® to deliver an extensive selection of high-quality silicone tubing and fluid handling products. Manufactured in the U.S. and Germany by Freudenberg Medical, HelixMark® products are available in a wide array of product types and sizes. Suitable for pharmaceutical non-critical flow applications. We offer a broad range of silicones from all the major manufacturers. Best of all, we deliver all our products on time, on spec, and on budget.

The choice of silicone you want

HelixMark® products are available with a choice of pharmaceutical- and medical-grade silicones made by industry leaders including Wacker, Dupont Liveo, NuSil, and Momentive. Elkem Silicones is also available for custom applications.

The custom services you deserve

Custom ID/OD sizing, custom labeling and certification, and a variety of packaging formats are available including bulk, spooled, and cut-to-length. Additional custom services include skiving, pad printing, bonding/gluing, punching, drilling, parylene coating, proprietary striping, and rapiopaque. Freudenberg Medical offers custom extrusions in a wide variety of tubing types including multi-lumen, intricate cross sections, co-extrusion, wire coating, profiles, rods, tapes, and formed tubing.

The quality standards you demand

HelixMark® products have been developed as a result of over 30 years of medical device manufacturing experience. We apply an ISO 13485 medical device quality system to all production and inspection processes and include material certification and lot traceability with every product. Our products meet USP Class VI biocompatibility requirements.

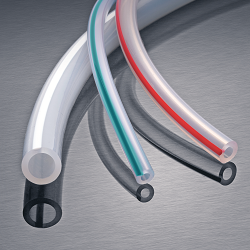

HelixMark® Standard Silicone Tubing

Full range of sizes, wide choice of silicones

HelixMark® Standard Silicone Tubing is available in a full range of competitive sizes in four choices of silicone elastomer: Dow Corning, Wacker, NuSil, or Momentive.

All HelixMark® Standard Silicone Tubing offerings are platinum-cured, and contain no additives, plasticizers, or peroxide components. The tubing is nonadherent and resists clotting, sticking, or encrustation. With the ability to operate at elevated temperatures, it will not oxidize or deteriorate. Rigorous testing, including expanded biocompatibility, provides quality assurance for the most demanding biomedical/pharmaceutical industry standards.

HelixMark Standard Tubing can be sterilized with autoclave, ethylene oxide, or gamma radiation within the user’s validated cycles and exposure levels.

For more information see our Size Chart.

HelixMark® Braided Reinforced Silicone Tubing

Ideal for increased pressure or high temperatures

Manufactured with our proprietary process incorporating strong polyester braiding between extrusions of platinum-cured silicone, our durable

Braid Reinforced Tubing with the identifiable blue spiral is ideal for increased pressure and/or high-temperature applications.

HelixMark braided silicone tubing can be sterilized by autoclave, ethylene oxide, or gamma radiation within the user’s validated cycles and exposure levels.

Typical hardness: 65 Shore A.

For more information see our Size Chart.

HelixMark® Double Braided Tubing

Ideal for elevated pressure & temperature

NEW – Double Braided Silicone Tubing is manufactured using a complex, multi-step process incorporating a strong layer of single braid polyester between two extruded layers of USP Class VI platinum-cured silicone followed by another layer of braided polyester and topped with a silicone over coat. Double Braided Tubing is difficult to manufacture and requires specialized equipment, complex systems and procedures, and advanced silicone extrusion expertise.

HelixMark® Double Braided Tubing is ideal for elevated pressure and high-temperature applications. Engineered with superior flexibility, Double Braided Silicone Tubing allows for excellent resilience. To meet a diverse range of application needs, it is constructed to prevent kinking and compression and can withstand high temperature and pressure.

Double Braided Tubing is available in custom colors, custom lengths, custom packaging and spools. It can be sterilized by autoclave, ethylene oxide, or gamma radiation within the user’s validated cycles and exposure levels. It imparts no taste or odor. All HelixMark® tubing is manufactured in a cleanroom within an FDA-registered manufacturing facility. All tubing products include material certification and full lot traceability.

Typical hardness: 65 Shore A

Typical Applications

- Pharmaceutical and biotech processing

- High volume, high pressure fluid transfer

- Purification processes

- High pressure and bulk liquid transfers

- Load cells

- Process lines

- Cell cultures

HelixMark® Color Stripe Tubing

Recognize lines at a glance

HelixMark® Color Stripe Silicone Tubing is available with three choices of color striping: red, green, or white. Whether you want to recognize your lines at a glance by application, tubing size, or functional area, HelixMark® Color Stripe Tubing gives you the flexibility to create your own system.

Add nonstripe and custom colors to create as complex a system as necessary.

Typical hardness: 55 Shore A.

For more information see our Size Chart.

HelixMark® Close Tolerance Tubing

Superior flow for exacting applications

Biomedical/pharmaceutical-grade platinum-cured silicone tubing, manufactured with Dow Corning, provides superior flow properties. HelixMark® close tolerance silicone tubing ensures minimal dimension variation, making this tubing appropriate for the most exacting applications.

Sterilize HelixMark® Close Tolerance Silicone Tubing by autoclave, ethylene oxide, or gamma radiation within validated cycles and exposure levels.

Typical hardness: 50 Shore A.

For more information see our Size Chart.

HelixMark® Peristaltic Pump Tubing

Longer life, superior strength, proven performance

HelixMark® Peristaltic Pump Tubing, manufactured with Wacker Silicones material, meets the strength and durability required for pump applications. Peristaltic Pump Tubing undergoes a stabilization process unique to Freudenberg Medical that provides the additional benefits of superior strength, performance, and longer life. Our tubing offers proven longer wear and volumetric consistency over 8-, 12-, and 24-hour process runs and is the most reliable and consistent platinum-cured silicone tubing available today for pumping applications.

Typical hardness: 60 Shore A.

For more information see our Size Chart.

Need pump tubing that has been extractables tested? See PharmaFocus® Peristaltic Pump Tubing

HelixMark® Black Opaque Tubing

For photosensitive drugs and light-sensitive fluids

Black-jacketed tubing is a custom extrusion offered by Freudenberg Medical. The tubing is manufactured to your exact specifications (ID/OD sizing and packaging format) and contains an opaque exterior layer to block all light without touching the fluid path. HelixMark® Black-jacketed Tubing is ideal for photosensitive drugs and light-sensitive fluids.

Black-jacketed Tubing is available with a choice of Dow Corning, Wacker, Nusil, Momentive, or Blue Star USP Class VI silicones. Material certification and lot traceability included in every package.

HelixMark® Silicone Stoppers

For tight, reliable seals

HelixMark® pharmaceutical-grade Silicone Stoppers are ideal for a tight, reliable seal for glass tubes, vials, and flasks. These platinum-cured silicone stoppers have full traceability to raw materials, contain no peroxide catalysts, and are autoclavable.

Available in 14 standard sizes. We also offer stoppers with pre-drilled holes.

For more information see our Size Chart.

Two-Hole Stoppers

Pharmaceutical grade silicone stoppers are platinum-cured and ideal for a tight, reliable seal. Two-Hole Stoppers have full traceability down to the raw material, contain no peroxide residues, and are autoclavable. Available in 16 standard sizes, hole diameter ranges from 3mm to 16mm.

Size chart

For more information see our Size Chart.

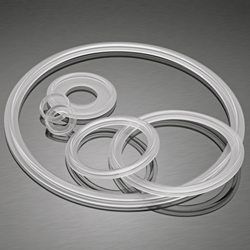

HelixMark® Silicone Clamp Gaskets

Crevice-free, protrusion-free, and biocompatible

HelixMark® pharmaceutical-grade Silicone Gaskets are made with our proprietary molding process and engineered to be consistently free of crevices and protrusions. The gaskets have exceptional biocompatibility and contain no contaminants or leachables. Clamp gaskets are sterilizable by autoclave, ethylene oxide, or gamma radiation within validated cycles and exposure levels.

Size chart

| Type | Inside Diameter | Inside Diameter | Part No. - North America | Part No. - EU/APAC | |||

|---|---|---|---|---|---|---|---|

| inch | mm | ref number | ref number | ||||

| Mini | 0.5 | 12.70 | 70-400-05 | 45639005 | |||

| Mini | 0.75 | 19.05 | 70-400-07 | 45639007 | |||

| Standard | 1.0 | 25.40 | 70-400-10 | 45639010 | |||

| Standard | 1.5 | 38.10 | 70-400-25 | 45639015 | |||

| Standard | 2.0 | 50.80 | 70-400-20 | 45639020 | |||

| Standard | 2.5 | 63.50 | 70-400-25 | 45639025 | |||

| Standard | 3.0 | 76.20 | 70-400-30 | 45639030 | |||

| Standard | 4.0 | 101.60 | 70-400-40 | 45639040 | |||

| Standard | 6.0 | 152.40 | 70-400-60 | 45639060 | |||

Values listed are typical. Please contact customer service for tolerance and custom size requests.

| Specifications | |||

|---|---|---|---|

| ISO 10993-1 | FDA 21 CFR 177-2600 | USP Class VI | EP 3.1.9 |

Packaged 12 per zip bag in crush-resistant boxes. Material Certification and Lot Traceability included in every box.

Custom Services

Excellence is customary

Custom Assemblies

Dedicated to saving time

Utilize Freudenberg Medical’s dedicated assembly expertise to free up valuable employee time. Combine tubing, stoppers, and gaskets with complementary parts such as barbed tubing connectors, tri-clamp compatible fittings, or luer adapters. Options can include full preassembly or simply component inclusion.

Custom Packaging

A full array of options

Whether you want to reduce bag and box waste or eliminate time-consuming cutting of tubing to specified lengths, Freudenberg Medical can accommodate your needs. Consider our array of alternative packaging options, including:

- Spooling (amount on spool determined by tubing outside diameter).

- Bulk coil packaging (multiple standard coils in each box).

- Pre-cut lengths (as short as mere fractions of an inch to many feet, cut to your specified tolerance).