White Papers

-

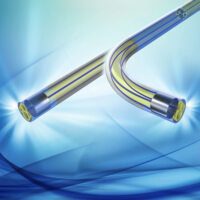

Incorporating Advanced Steerability into Your Catheter

Physicians have increasing expectations for better performance and increased functionality in the minimally invasive catheters and delivery systems they use.

The ability to steer a catheter with confidence and ease through challenging anatomies and deflect the tip for precise placement at its final target is essential. In this white paper, Freudenberg Medical delves into the key design and development considerations to incorporate advanced steerability into a catheter. -

Essential Guide to Hypotube Design

In minimally invasive surgery, the best patient outcome begins with navigating the vasculature safely and smoothly.

Freudenberg Medical's essential guide to hypotube design will help you optimize your hypotube component and understand the key manufacturing processes required to create the perfect access or delivery catheter. -

Opening the Door to Material Substitution

Breaking the hold on single-source suppliers creates a less costly and more sustainable material supply chain for medical device manufacturers

Today, many medical device manufacturers are relatively “cemented in” using one material provider. Oftentimes, they are not aware of the full scope of materials available on the market that might fill an application. -

Critical Considerations When Molding Diagnostic Cartridges The molding of diagnostic cartridges, lateral flow components, and intricate microfluidic devices requires expertise in mold design, injection molding, and in-vitro diagnostic device manufacturing to ensure the successful production of high-quality, validated, and scalable components. When molding diagnostic cartridges there are several key considerations to incorporate into your project scope. Learn more

-

Two Component Molding

Solve Medical Design Challenges and Reduce Costs

Device manufacturers count on their supply chain partners for answers. What processes can be adjusted to add value and reduce cost? What methods can be used to streamline manufacturing processes, reduce SKUs, and improve part quality? One way is by moving from single component molding to two-component molding. Learn more -

Freudenberg Medical Achieves Break-through in Measurement Technology for Silicone Tubes with Helix iMC™

New inline process provides precise geometric measure of inner diameter

In a worldwide first, Freudenberg Medical introduces a ground-breaking new technology to continuously measure the inner geometry of silicone tubes. The new technology significantly increases product quality for high precision applications such as pacemaker lead insulation and dramatically cuts down on material usage and process time. -

New Catheter Based Devices And Procedures Driving Hemostasis Valve Innovation

The viability of new interventions depend on more robust componentry

Today’s hemostasis valves are a vexingly difficult engineering challenge. Beyond the minimum requirements per ISO11070 and ISO10555 for pressure and vacuum decay, emergent invasive catheter therapies are demanding much more from the introducer componentry, especially the hemostasis valve. In this article, we review some of the factors rendering older valves inadequate, and some things to consider when choosing a device development partner. -

Extrusion, a Central Process in Catheter Development

The extrusion and catheter finishing processes are inextricably linked and balancing these processes can be a complex undertaking

-

In-Line Laser Marking of Silicone Tubing

The process of choice for the permanent marking of tubing without adding any ink or material to the extrusion.

-

The Silicone... Makes all the Difference

Medical and pharmaceutical applications benefit from platinum-cured silicone combined with advanced processing techniques

-

Scientific Injection Molding

A tool for Lean Manufacturing Published in Medical Design Technology