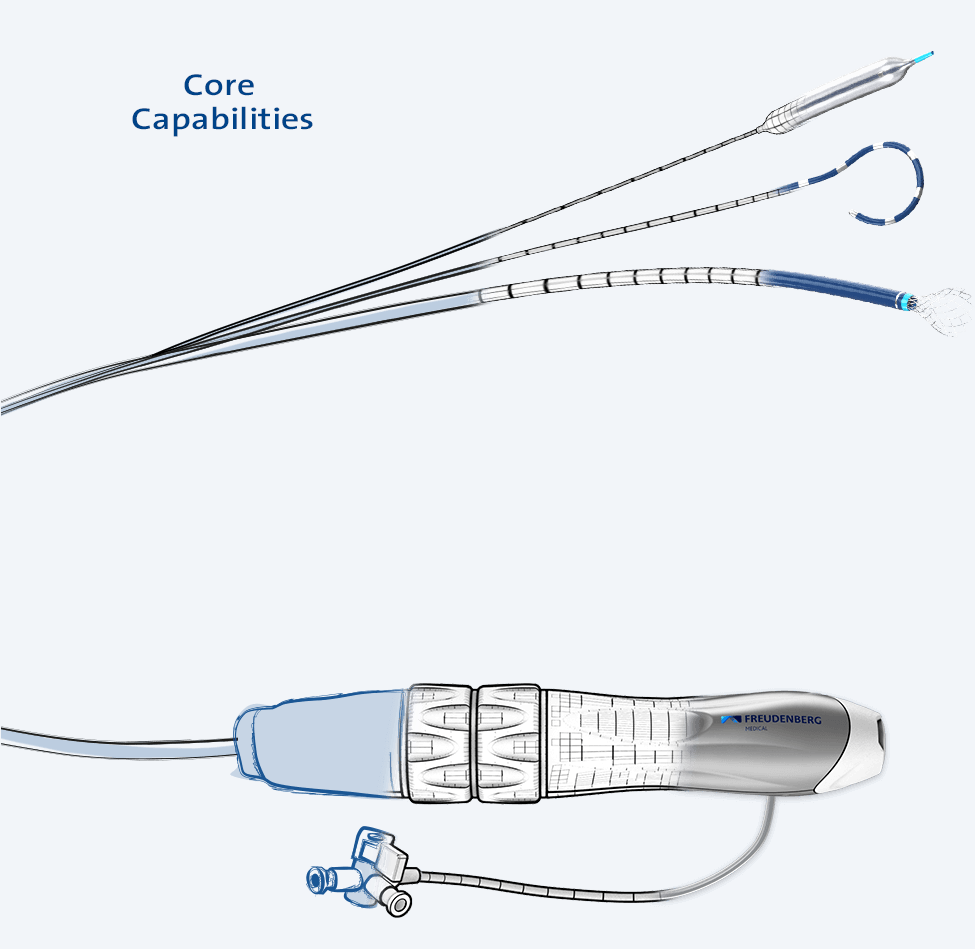

Medical Device Design & Development

Proprietary Processes, Proven Results.

At Freudenberg Medical, many of our sites are involved with medical device design and development. Our team uses a multi-phase design process to deliver the best products possible to our customers. This proven approach helps structure the flow of product development and ensures maximum collaboration at every step. Throughout the process we communicate frequently with our customers, provide consistent and timely production schedules, and thoroughly document each development process.

We co-develop breakthrough medical device designs using the latest tools and techniques to create products that are robust, safe, effective, and within budget. We develop manufacturing processes that ensure effectiveness all the way through to product launch. We also validate processes across the entire spectrum of product development – from bottom-up creation to parallel line-transfer.

Scroll through our core capabilities to learn more about our Design and Development offerings. Please contact us for more information.

Ideation & Prototyping

By combining experienced engineering resources with human factors and industrial design expertise, Freudenberg Medical is in a unique position to assist you through your concept development. Our world class ideation and prototyping capabilities include:

- Voice of the Customer Research

- Storyboarding and Communication Tool Development

- Authoring the Problem Statement

- Concept Development and Selection

- Bench Top Test Models

- Rapid Prototyping

Product Development

Freudenberg Medical has deep clinical experience developing and manufacturing complex catheter and medical device systems for demanding applications. We offer a breadth of product development capabilities that encompass everything from refinement of concepts and processes to test method development and design verification:

Product Development and Process Development

- Concept refinement

- Iterative loop testing and prototyping

- Design confirmation

- Design freeze/testing and documentation

Design Verification

- Characterization testing

- Engineering analyses (DOE, tolerance analyses, FEA, etc.)

- Review of historical data

- Animal and/or cadaver studies

- Design confirmation testing

- Product performance testing

- Biocompatibility testing

- Accelerated aging shelf-life testing

- Real-time shelf-life testing

- Packaging verification testing

Test Method Development

- FEA

- Reliability testing

- Limit testing

- Limited conditioning (humidity, temperature, etc.)

- Bubble emission package testing

- Tray/pouch seal testing

- Ex-vivo testing

- Sterilization validation

- Material biocompatibility testing

- Dye penetrant package testing

- Full package conditioning/ship testing/aging

- Surface analysis

- SEM material analysis

Design for Manufacturability

Freudenberg Medical’s teams are equally comfortable working in clinical and pre-clinical environments and have an unrelenting commitment to quality. Products built here go through a rigorous quality control process that delivers defect-free and timely results. Capabilities we provide during the Design for Reliability/Manufacturability phase include:

- Early involvement of process and manufacturing engineers

- Robust internal procedures for design transfer

- Early engagement with the customer and supply chain

- Cross functional review of manufacturing process

- Equipment selection

- Lean approach and lean tools such as 3P

- Statistical data analysis

- Process characterization starting prior to qualification

- For complex catheters - leveraging internal capital equipment and previously developed processes

- Experience