Materials, Products & Technologies

There are no constraints to our material and technology capabilities

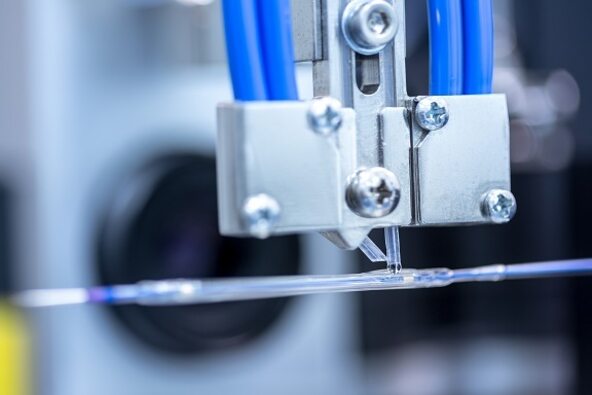

Freudenberg Medical partners with customers to offer end to end contract medical device manufacturing services. As an organization, we pride ourselves on having no limits to what we can do with complex materials, technologies and processes. Whether you’re looking for thermoplastic tubing with tight tolerances, a medical grade silicone insert molding solution, a minimally invasive catheter solutions, or you simply don’t know what you need just yet, our experienced team of engineers will assist you through the entire process.

43 of the 50 largest medical device companies in the world trust Freudenberg Medical for:

-

Proven expertise in complex and conventional component and finished goods design and manufacturing.

-

Easy access to a highly efficient and cost-effective global supply chain.

-

Eleven manufacturing facilities worldwide – five of which are FDA certified – with consistent quality and tracking and standards across all global locations.

-

The ability to leverage over 200,000 corporate materials, method, and technology patents.

-

Access to staff-level PhD-level materials scientists in facilities around the world.

Please navigate our site to learn more about the value we can provide to you.