We deliver Growth and Innovation

Freudenberg Medical is a global partner for the design, development and manufacturing of innovative medical device technologies. We combine a team of world class engineers with an unmatched range of global resources managed through a single source relationship.

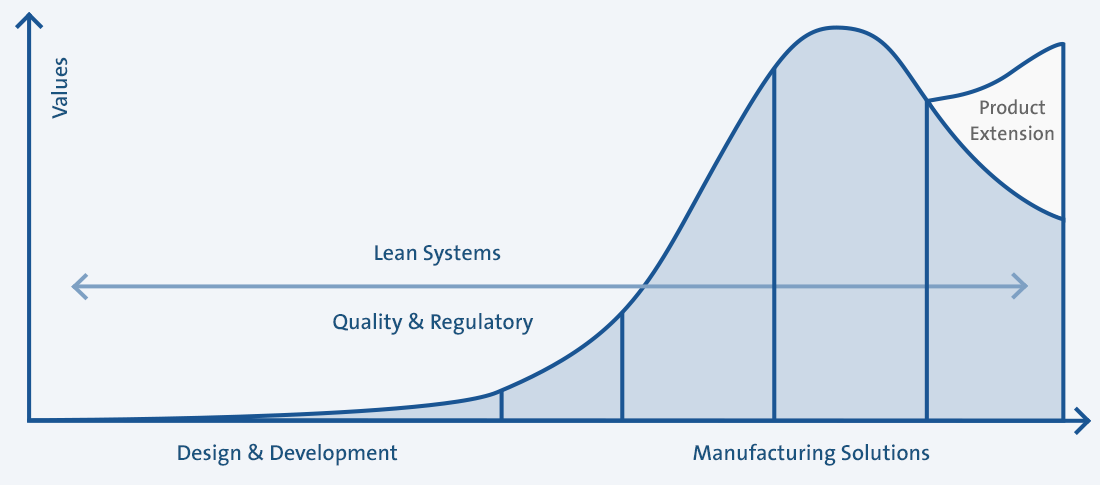

Product Lifecycle

Design & Development

Manufacturing Solutions

Click on one of the phases to learn more!

Ideation

- Creativity Techniques

- Freedom to operate studies

- IP & Patent support

- Quality and Regulatory support

Product Development

- Industrial design

- Materials selection support

- Rapid protoyping

- Design validation / verification

- Sterilization validation

- Quality and Regulatory support

- Lean systems (e.g. VA/VE)

Design for Manufacturability

- CAE (FSI, FEA, CFD, Moldflow)

- Rapid prototyping / rapid tooling

- Quality and Regulatory support

- Packaging design and validation

- Lean systems (e.g. 3P)

Product Launch

- Precision Component Manufacturing Silicone/ TP Molding/ Extrusion, Hypotubes, Coatings

- Full device Assembly & Subassemblies

- Sterilization

- Full Packaging

- Lean systems (e.g. Complexity Management, 3P/VSM)

- Quality and Regulatory approval

Growth

- Lean Systems support

- Adjusting production strategy to forecasted volumes

- Reviewing procurement strategy

- Lean systems (e.g. VSM, Shop floor manual, Synchronized Processes)

Maturity

- Lean Systems support

- Adjusting production strategy to forecasted volumes

- Transferring projects to low cost countries

- Optimizing procurement strategy

- Lean systems (e.g. Awareness to avoid waste)

Product Extension

- Review design and functionality options

- Review manufacturing options

- Lean systems (e.g. Complexity Management, 3P)

Our comprehensive technical capabilities range from the design and manufacturing of minimally invasive, catheter, and handheld technology to the development and production of medical components utilizing complex materials and processes. We lead the way in the manufacturing of high precision silicone and thermoplastic components and tubing as well as metal hypotubes.

The world’s leading medical device companies have confidence in Freudenberg Medical because we:

-

Provide flexible deal structures to help customers optimize business performance by aligning revenue and expenses, optimizing balance sheet performance and minimizing tax burden.

-

Have multiple PhD level materials scientists on staff and provide the ability to leverage thousands of corporate materials, method and technology patents.

-

Deliver cost-efficiency and quality through our proprietary GROWTTH® manufacturing process and have a proven track record for producing compliant products with zero defects.

-

Provide best in class total program management skills with a demonstrated ability to design for transfer to manufacturing.

Please navigate our site to learn more about the value we provide to our customers.